Rust Never Sleeps

I’m not an uptight guy, certainly not when it comes to keeping my stuff clean. The dog hair frosting the hardwood floor in my office? I’ll vacuum it up tomorrow. My canvas hunting jacket, so prickly with briers it looks like porcupine skin? I’ll scrub and pick it clean at the end of the season. But I’m not a slob, either. I clean up after myself and take care of my gear. It’s just that dirt will always be a part of life, and life is too short—my days are already full. I would rather chase birds than dust.

I’m better about cleaning my shotguns. After a hunt, once the dog is fed and the game is prepped, I’ll break down my side-by-side, run a fuzzy bore-cleaning rod down its barrels, and wipe away any dirt, sweat, and fingerprints along the exterior with a silicone cleaning cloth. Done. I put the shotgun back in its case and move on to dinner and the best part of the post-hunt evening: relaxing, with a book in my hand, and my pointer curled up in my lap.

Fortunately, I shoot modern ammunition. Modern shotgun shells are noncorrosive, and this supports my “do-it-later” cleaning ways. In the past, ammunition worked all sorts of evils on firearms. First there was blackpowder, the most common propellant up until around 1900. Blackpowder is hygroscopic, and the fouling it leaves behind attracts moisture like salt in a shaker. This moisture leads to rust, which is why so many old doubles are pockmarked and pitted. Similarly, old shotshell primers contained substances such as potassium chlorate. These chemicals left behind salt deposits on the breech face and action every time a gun was fired. These salts attracted moisture—and if they were not cleaned away, rust followed.

These days, most commercial shotgun shells contain smokeless powders and noncorrosive primers. Problem solved.

If you like billowing clouds of white smoke, you can still buy blackpowder loads. But be warned: After firing blackpowder shells, you’ll need to break down your gun and clean away the fouling right away. Shooting blackpowder is too much work for me—but I do have other concerns about my shotguns. So every couple months, I pull out my side-by-sides and O/Us and give them thorough cleanings.

I grew up hunting. My dad gave me a sporting gun when I was 12, and I bought my first shotgun when I was 15. Still, I’ve learned most of what I know about gun dogs, shotguns, and hunting from other people. I’m blessed to know a handful of patient, knowledgeable friends who take the time to answer my questions and show me what’s first rate and what’s not. My friend Ed has taught me a lot about fine shotguns, including how to care for them. I thought I already knew how to clean a shotgun. Ed showed me I didn’t come close.

Ed loves old double guns as much as I do, and on any given day I can stop by his house and take a look at a 12-gauge Boss side-by-side or a Woodward over-and-under. Ed shows me the details that make these guns so special: the shaping of their actions, the elegant fore-end tips, the benefits of certain ejectors.

For my cleaning lesson, Ed used a little 20-gauge Belgian sidelock side-by-side made between the World Wars. He had shot a few rounds of sporting clays with it earlier in the week and had already done a quick job of mopping out the bores and wiping it down—a “superficial cleaning” he called it (and something I’ll begin doing from now on after shooting any of my own doubles).

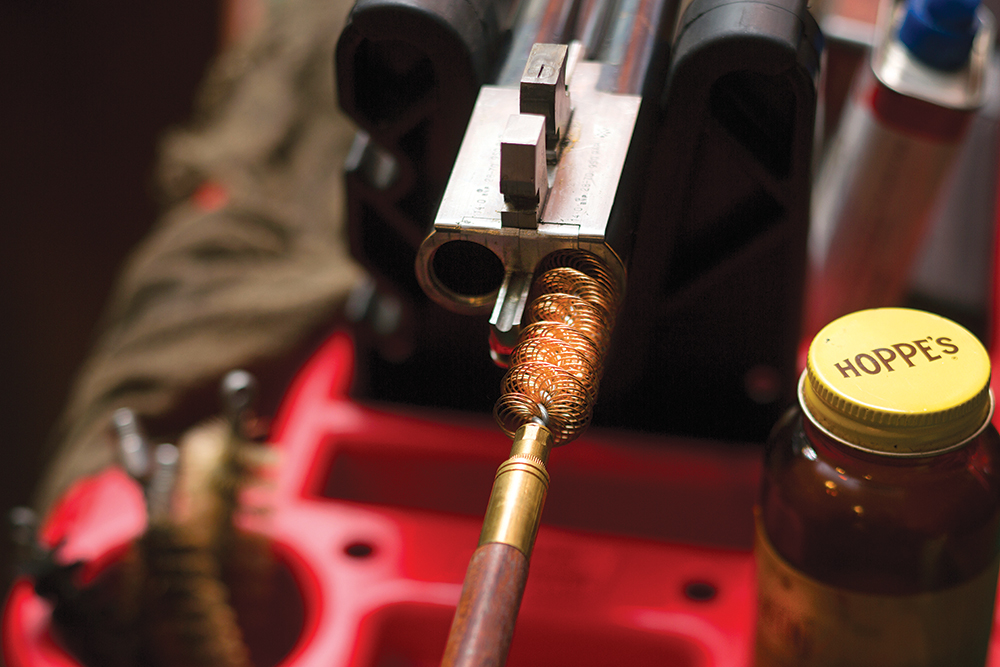

For his gun’s thorough cleaning, Ed broke down the double and set the barrels, action, and fore-end on his workbench. We were going to start with the bore, and Ed lined up the tools and supplies for the job: a cleaning rod; some bore solvent; a spray can of gun oil; some fine steel wool; a prickly, bronze tornado brush; a fuzzy cotton bore mop; and a finger-high stack of round, flannel cleaning patches.

While any cleaning rod long enough to sweep the barrels will do, Ed prefers traditional, one- or two-piece wooden rods with long, knurled handles. These rods are sturdy, and they give you plenty to hold onto. Unlike using stainless-steel rods, if you’re clumsy you don’t have to worry about the wooden shafts scratching your shotgun’s bores or marring the ejector rods, chamber rims, or other parts.

Ed’s also a traditionalist when it comes to bore solvents. He uses Hoppe’s No. 9. I love Hoppe’s No. 9. I’ve used it since I was a kid, and its aroma brings to mind baize-lined leather gun cases, fine shotguns, and days in the field. There are a couple of things to note about the product, though.

First, Hoppe’s No. 9 is a solvent. It dissolves stuff. Leave a speck of it behind, and it will go to work on the metal or wood right away. So be sure to wipe away all of it as soon as possible. Second, while Hoppe’s No. 9 is great on powder residue, it doesn’t do a great job on wad fouling. The one-piece, polyethylene wads used in modern shotgun shells cause wad fouling. Every time you fire one of these shells, bits of polyethylene melt onto the bores. Shoot several hundred rounds, and you’ll have layers of fouling. Moisture can get trapped underneath these layers, and we know what moisture leads to—rust. To remove wad fouling, use a dissolvent like Shooter’s Choice Shotgun and Choke Tube Cleaner instead of Hoppe’s No. 9. Follow the instructions on the can, and be prepared for a mess.

Now let’s go back to the cleaning. Once everything was in order, Ed locked the barrel’s lumps into a blue Wilton Bullet Vise bolted to the side of his workbench. Very smart, I thought. The vise’s jaws locked the barrels into a horizontal position and kept them secure. Ed’s hands were now free to tend to the cleaning job. He could scrub the bores without having to worry about dinging the blueing on the outsides of the tubes. To protect the barrel’s lumps, Ed folded lead sheets over the vise jaws. Thin pieces of wood also work. If you’re going to use a vise, be sure you use one or the other.

Once the barrels were locked into the vise, it was time for the Hoppe’s. Ed worked it into the bores by screwing the bronze tornado brush to the end of the wooden rod, splashing some solvent on a cleaning patch, wrapping the patch around the brush, and then running the whole thing through each barrel a couple times. Then he paused to give the solvent time to work.

While we waited, Ed explained that I should always clean a gun from the breech end to the muzzle. This way, the gunk I’m pushing out of the tubes ends up on the workbench, instead of in the chamber rims and around the extractor rods.

After a few minutes, Ed went back to work. This time, he wrapped the bronze tornado brush in fine steel wool and ran it through the barrels several times. This was to break up and wear away the residue dissolved by the Hoppe’s. Then Ed swapped the steel wool for a clean flannel patch, swept the barrels, and repeated. The first patch came away black; the final one was almost clean. The last step was to spray a bit of Rem Oil onto the cotton mop, attach it to the rod, and run it down both tubes. Now the bores were cleaned and oiled. We were ready to move on to the rest of the gun.

Fouling in the bores is your main focus when cleaning a gun, but there are other concerns—dust and dirt, plus blood, sweat, and fingerprints—that can wreak havoc on your double, and the sooner you clean them away, the better. Blood, sweat, and fingerprints can lead to corrosion, while dust and dirt are abrasive, especially when they work their way into old gun oil and form a primitive kind of lapping paste.

To clean away all of it, Ed used a handful of Q-tips, an old toothbrush, and a cotton rag. First, he scrutinized the exterior of the barrels, paying close attention to the top and bottom ribs, the fore-end loop, the bites on the lumps, the ejector rods, the action flats, and the chamber rims. Anything suspect he wiped away with a Q-tip or the cotton rag. Anything that remained was given a gentle scrubbing with the toothbrush plus a teardrop of Hoppe’s No. 9, and wiped away with the rag.

Then Ed checked the fore-end iron, action, trigger guard, and top lever. After all were judged clean, he turned to the fore-end wood, stock, and checkering. All sorts of muck can end up on a stock and embedded in the checkering—pine sap, blood from a bird, mud from a wet dog—and while most won’t do much harm to the wood, it will do harm if it finds its way onto the metalwork. Get rid of it as soon as you can. For gunk in the checkering, a few sweeps with a nylon toothbrush will do. Just make sure it’s not the same toothbrush to which you applied the Hoppe’s No. 9.

Once Ed’s little 20-bore was clean, it was time to lubricate it. For this, Ed opened a cabinet and pulled out several fine, sable-hair paintbrushes and a can of Lubriplate 630-AA—a thin, lithium-based grease that’s waterproof and, according to the manufacturer, “designed to stay put in all kinds of weather.” The “stay put” is important. Excess oil—particularly if it’s petroleum-based—can attract dust, run off the metal, and gum up the locks, ejector work, and top lever. It can also work its way into the wood and rot the fore-end and stock. Lubriplate stays where you put it and therefore doesn’t cause such problems.

Ed used the sable-hair brushes to paint a thin sheen of Lubriplate on the insides of the ejector rods, on the hook, bites, hinge pin—basically, wherever metal met metal. With a touch of Lubriplate on the tip of the brush, he worked away like an artist touching up a masterpiece. You don’t have to use Lubriplate; you can any light gun oil to lubricate your shotgun—Hoppe’s Elite, Ballistol, or if you can find it, old-fashioned Rangoon Oil. Just use it sparingly—less is best.

Now that the gun was lubricated, Ed moved on to oiling it. He had already coated the bores with Rem Oil, so next was to give the rest of the side-by-side a quick once over. For this task, Ed picked up a spray can of G96 Gun Treatment and another cotton rag. With a spurt of treatment applied to the rag, he wiped down the gun, focusing on the metal: First the barrels, and then the fore-end iron, and finally the action, top lever, top strap, and trigger guard. Ed said the G96 would not harm the wood, so he didn’t worry about getting a little on the stock or fore-end. (If you’re using another kind of oil, learn more about its ingredients before letting it sit on the wood.)

Once the oiling was done, Ed reassembled the shotgun, gave it a final wipe down with a Selvyt cleaning cloth, and locked it away in his gun safe. British gunmakers traditionally included Selvyt cleaning cloths with their new doubles. These cloths were emblazoned with the maker’s logo—Ed’s cloth was from Holland & Holland—and using one to wipe down a prized side-by-side or over-and-under is a nice touch. A pedestrian (and less expensive) choice is a regular silicone-impregnated cleaning cloth. It cleans just as well and leaves behind a protective, rust-inhibiting finish.

As Ed closed and clinked shut his gun safe, his master class came to an end. His little Belgian 20-gauge was ready for another day—and the education was so good, I now knew enough to get to work on my own guns.

I grew up hunting. My dad gave me a sporting gun when I was 12, and I bought my first shotgun when I was 15. Still, I’ve learned most of what I know about gun dogs, shotguns, and hunting from other people. I’m blessed to know a handful of patient, knowledgeable friends who take the time to answer my questions and show me what’s first rate and what’s not.