Cigar Anatomy

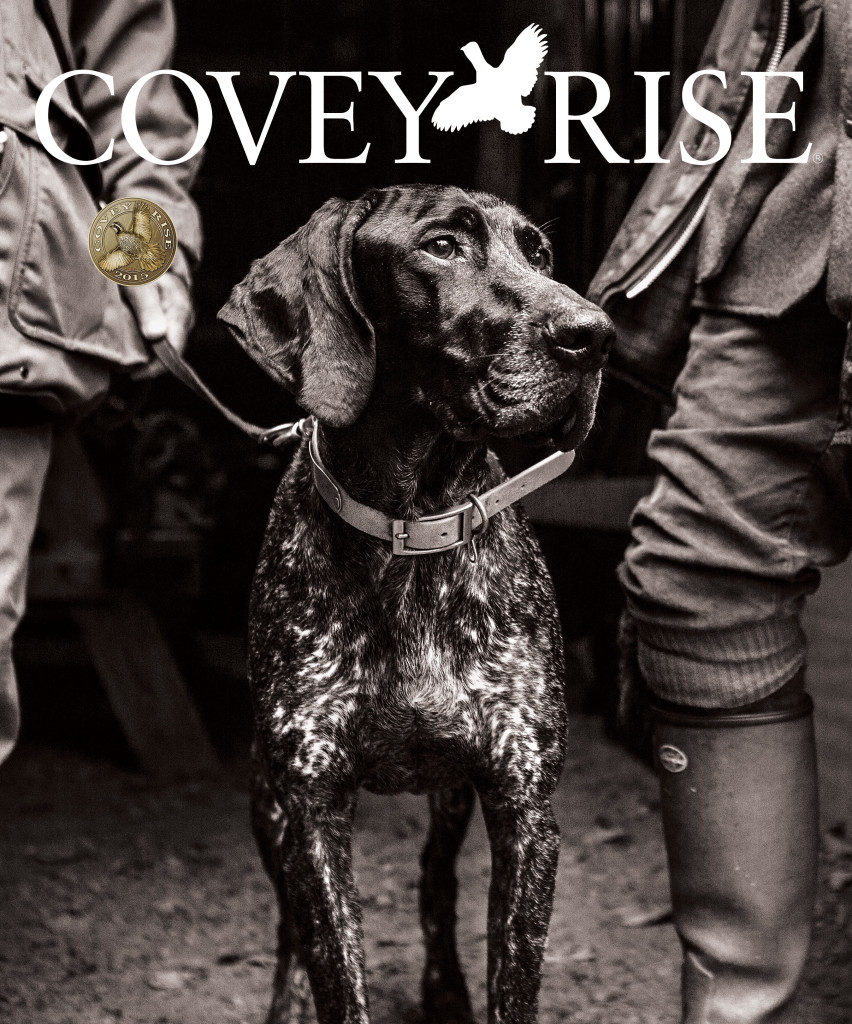

A deeper understanding of our hobbies and pastimes leads to greater enjoyment of those passions. Isn’t that a prime motivation for visits to wineries and distilleries? That’s also why a curiosity about their favorite beverage leads many beer enthusiasts into home brewing. Similarly, a love of hunting is undoubtedly why readers of Covey Rise enjoy articles about bird dogs and shotgun manufacturers.

These sentiments are also true for cigar smokers. Learning about cigars—their history, tobacco cultivation, the curing and fermentation process, and the skills involved in cigar rolling—increases our appreciation of a cigar and heightens the pleasures delivered by the handmade masterpieces we love to smoke.

Creating a premium cigar begins with a carefully crafted and well-tested formula for combining tobacco leaves to deliver a specific taste profile. Recipes are fashioned by master tobacco blenders who rely on their discriminating and sophisticated palates and their intimate knowledge of tobacco.

Designing a cigar requires artistry, some science, and just a bit of magic. Leaves from different parts of the tobacco plant vary in taste, strength, and burn rates, so the recipe must balance and combine flavors while accommodating a variety of combustion speeds. It’s a complicated process that very few master; but when done right, the result is a delicious, even-burning cigar that is a pleasure to smoke.

All premium cigars—no matter the shape or size—are composed of three distinct sections. These are the three areas in which the tobaccos prescribed by the blender’s recipe are combined to create a cigar. It begins with the inside of the cigar—this first section is the filler. That’s followed by the binder. Finally, the outer leaf is known as the wrapper. One, two, three.

The filler is considered the heart of a cigar because it sits in the center and contains the majority of the tobacco. Depending on the size of the cigar and the recipe, the filler could contain up to five different types of tobacco, each with distinct characteristics from growing regions around the world. Bunched together in the filler, the different tobacco flavors blend during smoking to give a particular cigar its unique taste profile.

The filler tobacco in a premium cigar consists of whole tobacco leaves that stretch from the cigar’s head to its foot. This is known as long filler and contrasts with short filler cigars that are comprised of tobacco scraps. Long filler tobacco delivers a more consistent flavor, a more even burn, and consequently a much better smoking experience than short filler does.

Once the filler tobacco is combined and bunched into a cylindrical shape by the expert hands of the torcedore or cigar roller, it is wrapped in the binder leaf. As the name implies the purpose of this tobacco leaf is to bind or hold the filler together. The binder is usually a thick, tough leaf that compliments the strength and taste of the filler tobacco.

After the binder is wrapped around the filler, the combo is placed in a mold and up to 45 minutes of continuous pressure is applied to entice it into its final cigar shape. The only exceptions are planned interruptions to give the filler-binder combination a slight turn in the mold to prevent the formation of ridges and seams. With the completion of the molding process, the filler-binder combination begins to resemble a cigar and is ready for the wrapper—the next step in the process

The wrapper is applied by a roller to the filler-binder combination as it is removed from the mold. It is usually a single leaf of tobacco selected for its appearance, elasticity, color, and flavor. Only high-quality and, at times, very rare leaves that are free of imperfections are used. Often, the wrapper is the most expensive part of a cigar and considered by many to be the most important component.

Not only does the wrapper leaf give the cigar its feel and appearance; it also delivers a surprisingly high percentage of the cigar’s flavor. Some estimates of the wrapper’s influence on flavor run as high as 40 percent, depending on the filler tobacco and the size of the cigar.

At this point the cigar is nearly complete. However—one last important step awaits. That final component is the cigar cap. The cap is small piece cut from the wrapper leaf. Its purpose is to provide an attractive cover to the head of the cigar, while securing the wrapper in place. The cap is what we cut or pierce just before lighting and smoking.

Placing the cap on the head of the cigar means that the cigar is complete. The filler, binder, and wrapper have been skillfully combined to create a premium cigar with each section working together to deliver a unique, delicious flavor and a satisfying smoking experience.

Learning about cigars—their history, tobacco cultivation, the curing and fermentation process, and the skills involved in cigar rolling—increases our appreciation of a cigar and heightens the pleasures delivered by the handmade masterpieces we love to smoke.