The Road to Damascus

Ignorance impairs the circulation of sound advice, and sometimes we wind up influencing others with our faulty guidance. Such was the case several years ago when my coworker Kim introduced me to her great grandfather’s Parker Brothers 20-bore. She knew little about the old double gun, and assuming that I knew more, invited me over to take a look. Kim and her husband lived within walking distance from our office, and when quitting-time came, I went over to see her treasured heirloom.

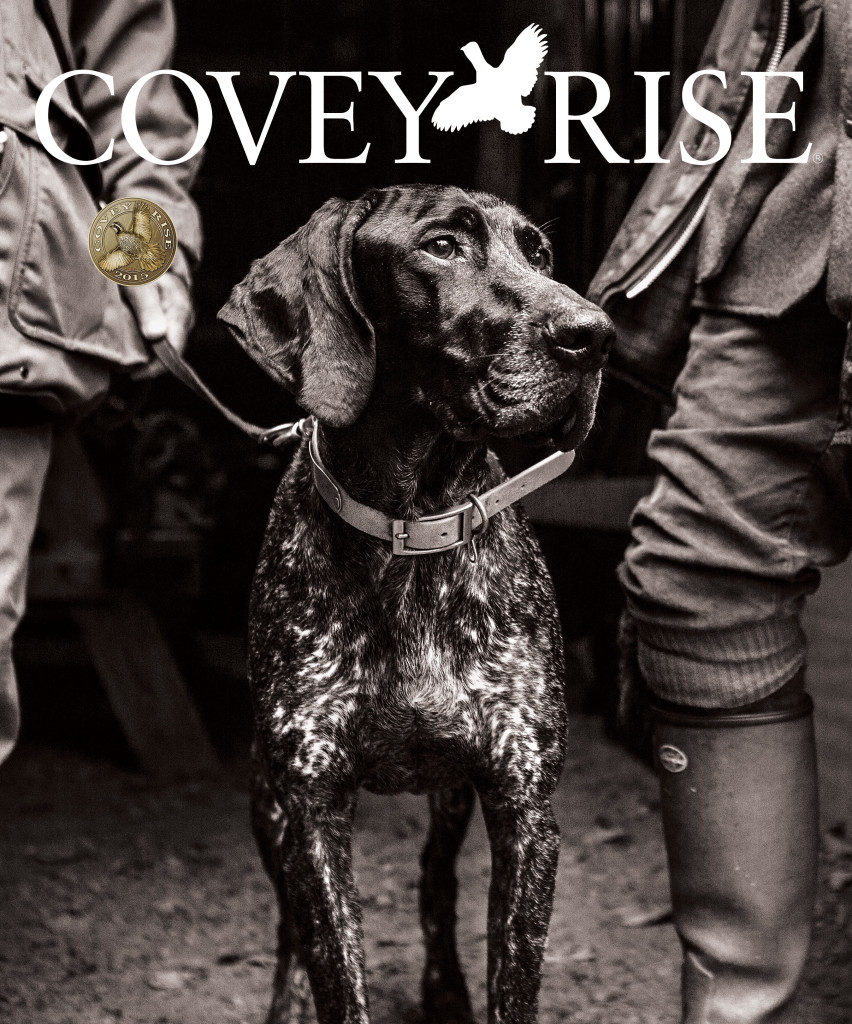

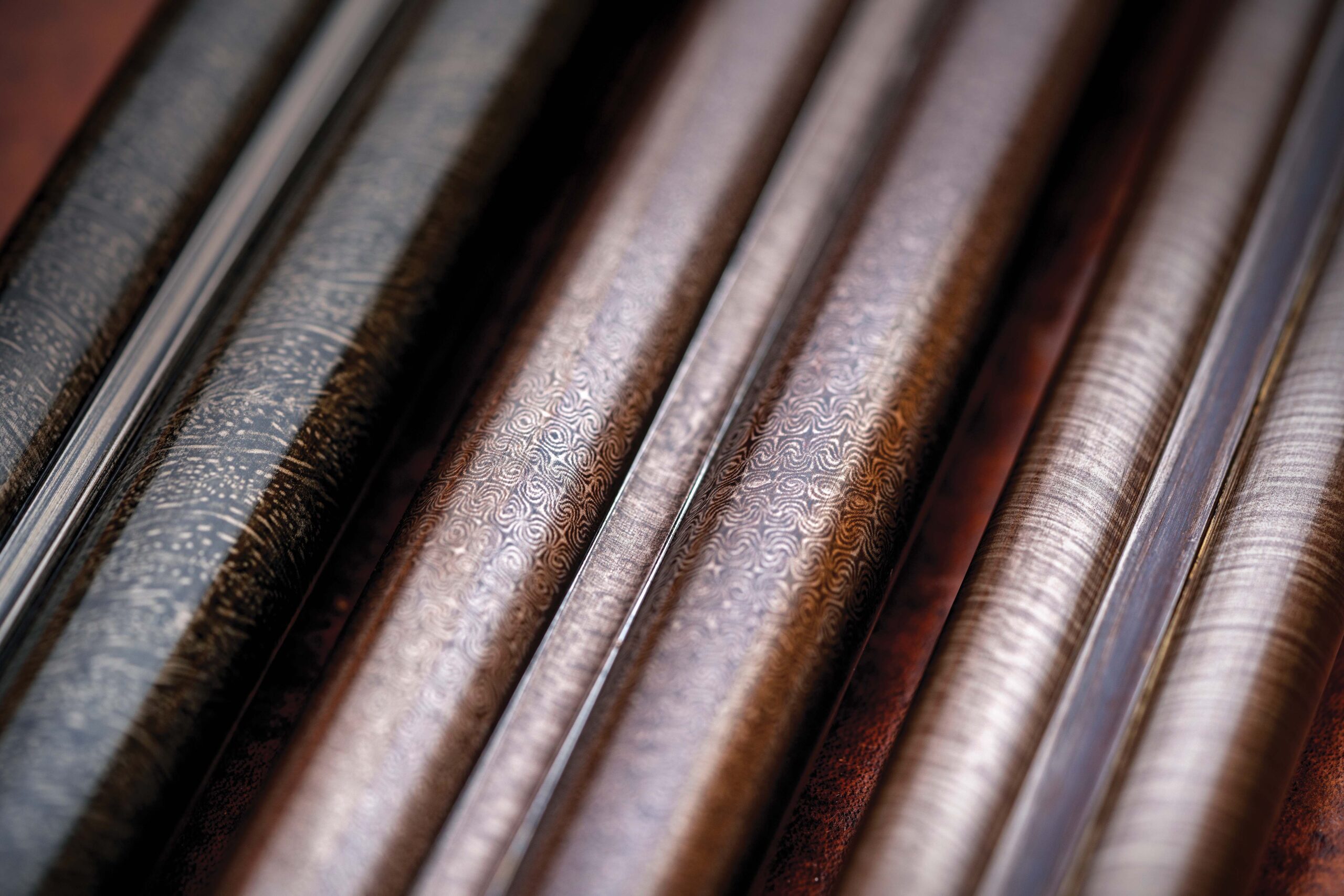

Before Kim retrieved the Parker, we cracked a couple of cold beers on the porch to close the workday. She returned from inside the house with a maker’s case of wood and well-worn leather. The hinges of the case creaked and cracked like a crepitus joint as she opened it, but the Parker it protected looked exceptional. The oil finish on the walnut stock still dazzled despite some nicks, suggesting the gun received a regimen of tender care after a day afield. Crisp engraving on the action revealed a setter on point, surrounded by deep scroll and a banner bearing the gunmaker’s name. A pair of Damascus tubes showed no speckling or pitting inside or out. When I hung them on my index finger by the barrel lump and thumped them, they rang like a bell. I mated the barrels to the action and attached the fore-end, then balanced the weight of the Parker in my open palm at its hinge pin.

I took a shooting stance and shouldered it, then opened the action and grinned before saying to Kim, “That’s a very nice Parker, but the Damascus barrels present a problem.”

“What do you mean? What are Damascus barrels,” she replied.

I “mansplained” what little I knew about them before she confessed to having fed the gun cartridges loaded with nitro powder…and that she’d done it more than once. I asked her if the barrels were sleeved, to which she replied, “I have no idea.” Upon hearing this, I frightened her with more mansplaining before saying, “You’re lucky it didn’t blow up. Keep it oiled and hang it on the wall.”

The advice I offered was certainly safe—in the same sense that never leaving your home in an automobile is safe. And it wasn’t until years later that I learned my prejudices against Damascus guns resulted from almost a century of misguidance.

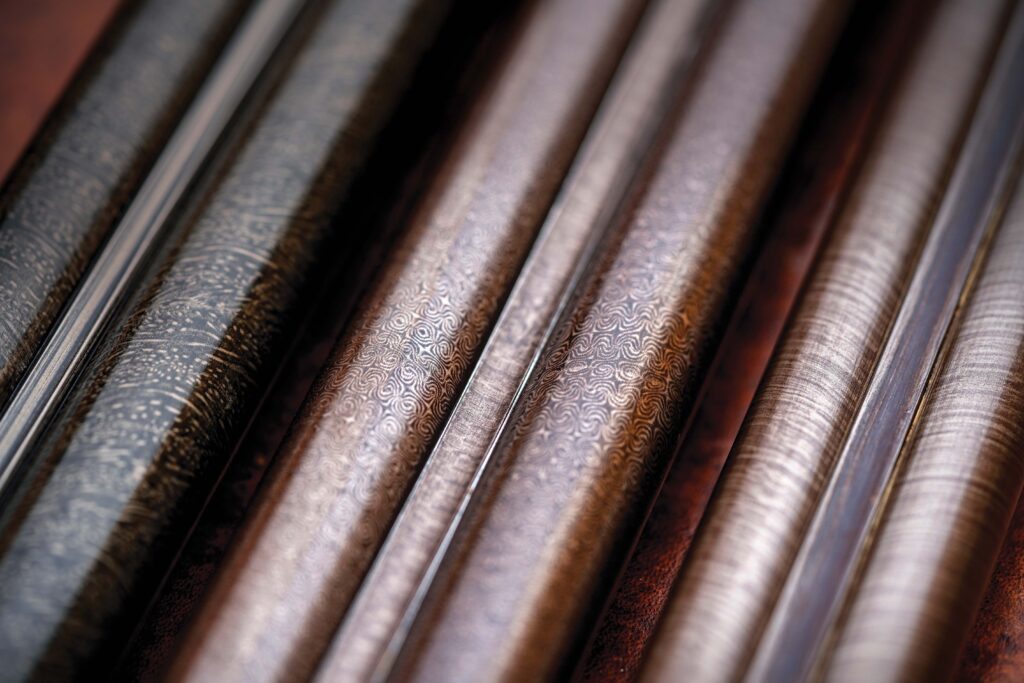

Finding the facts about Damascus-barreled guns involved sifting through lots of legend and lore. What we commonly reference as “Damascus barrels” are technically referred to as “pattern-welded barrels,” and there are three main types: Crolle Damascus, laminated, and twist. Pattern-welded swords from the Far East date back to before the common era, and given their reputation for strength and beauty, it made sense to forge pattern-welded gun barrels. As early as the 1600s, Eastern gunsmiths in India and Turkey applied pattern-welding techniques to the barrelmaking trade. The tools and process evolved, but well into the early 1900s, pattern-welded barrels were still being created by hand as they were centuries before.

Authentic pattern-welded (Damascus) barrels began as rods of iron and steel measuring several feet in length. Crolle Damascus, laminated, and twist barrel types are categorized by the technique used in their manufacture, as well as their ratio of metallurgical content. In all cases, iron-steel amalgam rods were heated, hammered, and twisted around a mandrel until a tube took shape. The tubes were then mated and soldered together along a center rib that matched the barrel tubes. An application of mild acidic solution to Crolle Damascus barrels revealed the grain of the metal—much like an application of oil reveals the grain of the wood—resulting in a marbled contrast between the iron and steel. Depending on the type of acid used, beautiful reddish-brown and golden-brown hues appeared like some feat of Faustian alchemy, and customers could choose the color and pattern of their Crolle Damascus barrels. Given proper care, many of these fine guns still wear their original finish.

Two major advances in firearms technology caused Damascus barrels to fall from favor. One was the advent of fluid steel, which produced stronger barrels at a reduced cost. Fluid-steel barrels were cast from melted steel that was pressurized, cooled, and bored into a barrel tube. The process eliminated microscopic pockets of air and other imperfections, resulting in a denser metal. The other technological advance was the advent of nitro (also known as “smokeless”) powder still used in contemporary cartridges. Nitro powder burns faster and produces greater pressures than traditional black powder, and due to the microscopic imperfections of some Damascus barrels, these higher pressures caused them to burst. Interest in Damascus barrels diminished due to these unfortunate accidents, and with the availability of stronger and more economic fluid steel, gunmakers deferred to market demand. The United States ceased using Damascus barrels by the turn of the 20th Century, and by the 1930s, makers in the United Kingdom and Europe discontinued their manufacture.

While supplies last, W.W. Greener offers its clients a set of Damascus barrels in addition to modern barrels. The tubes for these barrels come from surplus inventory made during the early 20th Century. James Purdey & Sons produces guns with Damascus barrels, but these barrels are not pattern-welded by hand. They consist of a proprietary damascene steel alloy built to withstand modern proof loads at the highest pressures. To the best of my knowledge, no major gun firms in the world produce pattern-welded barrel tubes in the authentic 19th and early 20th Century manner.

Before going further, I feel compelled to state that shooting any antique double gun without an inspection by a qualified gunsmith is foolish, and it is more foolish if shooting an antique double gun with Damascus barrels. Having said this, shooting nitro powder with well-built and well-cared for Damascus tubes is possible. It is less about the type of powder used and more about the pressures produced by the powder. This explained why my friend Kim still had her left hand, but what about all those Damascus guns with exploded barrels?

Inferior quality and unintentional abuse account for many of the incidents fueling the negative narrative around Damascus guns. Cheap knockoffs of fine guns were prolific during the early 20th Century, and barrel failures among them were common. At the time nitro powder arrived, many shooters handloaded cartridges, and some used the same measuring tools for nitro powder as they did for black powder. This inadvertently doubled and tripled the chamber pressures of their cartridges, and Damascus barrels of the highest order could not survive that level of abuse. The problem was compounded in the United States with our penchant for hotter, heavier loads.

While it is true that the vast majority of Damascus guns have over 100 years of wear and should not be subjected to high-volume shooting, under normal hunting conditions, they will perform as they did over a century ago—and with a gentle hand could perform for several more. Once a qualified gunsmith attests to the soundness of a double gun and its Damascus barrels, purchasing low pressure nitro-loaded cartridges from places such as RST Classic Shotshell Company presents an option for keeping it afield. It should be noted that using nitro cartridges in Damascus barrels involves more risk, especially in the United States with lack of a proofhouse and a shortage of qualified gunsmiths. That being said, a good number of shooters feed their Damascus-barreled double guns a diet of low-pressure, nitro-cartridges without barrel failure.

Choosing to shoot a Damascus gun with barrel-tube inserts presents another option. These tubes run the entire length of the barrels, and they shield the Damascus tubes from the ignition of the cartridge and the shot column. However, they have a considerable effect on the gun’s performance in regards to weight, bore size, and choke constriction. Speaking candidly, these tubes could turn a well-balanced, open-choked 12-bore into an eight-pound, oddly choked 20-bore. And low-pressure nitro cartridges would still be required to avoid cracking the barrel tube. Nevertheless, they do provide a solution for keeping a Damascus gun in the field.

Handloading black-powder cartridges presents an affordable and nostalgic—and perhaps meditative—option for those wishing to shoot the gun within its proof tolerances while maintaining its balance and handling. Handloading requires focus and attention akin to tying flies for fly-fishing. That presence of mind could become a soothing source of relaxation, along with the gratification of taking a bird on the wing with a handmade cartridge. And shooting a combination of black powder with paper-cartridge tubes creates an intoxicating aroma that billows from the barrel breeches. Handloading black-powder cartridges also offers a way to enjoy wingshooting without leaving any footprint on the resource. I can think of no cleaner cartridge for the environment than a handloaded black-powder charge with bismuth shot and fiber wadding housed in a brass tube.

Regardless of the cartridges used, Damascus guns must be cleaned immediately or as soon as possible, and if using black powder, greater urgency is required. After ignition, black powder leaves behind a hygroscopic residue that attracts moisture from the air, and it will corrode the barrels faster than anything other than salt water. Caring for a Damascus gun after use with black powder involves a different, but simple and inexpensive cleaning process. First, mix a solution of common dishwashing liquid and piping-hot water. Next, soak a cotton patch with the hot, soapy water and push it through the barrels. The patch should fit snug against the barrel walls, but not so tight that it cannot be pushed through the muzzle with reasonable pressure. Repeat this step until the patches are spotless, then run a dry barrel swab to mop up any moisture. Spray the bores with Ballistol and swab them again to coat them with a layer of moisture protection. Finally, wipe the outside of the barrels with a Ballistol-soaked rag, taking care not to leave fingerprints, and reassemble the gun. Proper storage of a fine gun draws differing opinions, but many shooters favor storing them horizontally, or vertically with the barrels down.

Despite overwhelming evidence to the contrary, some still argue that Damascus guns should not be used afield. I was also unappreciative of their quality and value, but I now extol and covet them. Imagine the barrelmaker enduring the heat of a fiery furnace, sweat falling and hissing on the hot steel as he poured his labor into them. Now visualize the sunlight glinting off the marbled metal on a bluebird day as you pause and acknowledge the rich history held in your hands. The broader market seems to undervalue such qualities, because an accurate accounting of the craftsmanship and character of Damascus-barreled guns would demand a stratospheric price point. Brothers and sisters, the scales have fallen from my eyes and they have beheld the glory of Damascus-barreled guns. Go forth and spread the good news—Hallelujah!

Originally published in Volume 10, Number 2 (Feb-March 2022) of Covey Rise.